What if you could revolutionize the way your business handles printing by adopting technology that’s fast, versatile, and produces stunningly high-quality results? Enter UV printing. This technique is rapidly transforming the printing industry, offering advantages that traditional methods simply can’t match.

This article will explore everything you need to know about UV printing—from what it is and how it works to why it’s taking the printing world by storm. We’ll also break down five reasons UV printing is the future of high-quality printing. By the end, you’ll see why this technology is a must-have for any business looking to stay ahead of the curve.

What Is UV Printing?

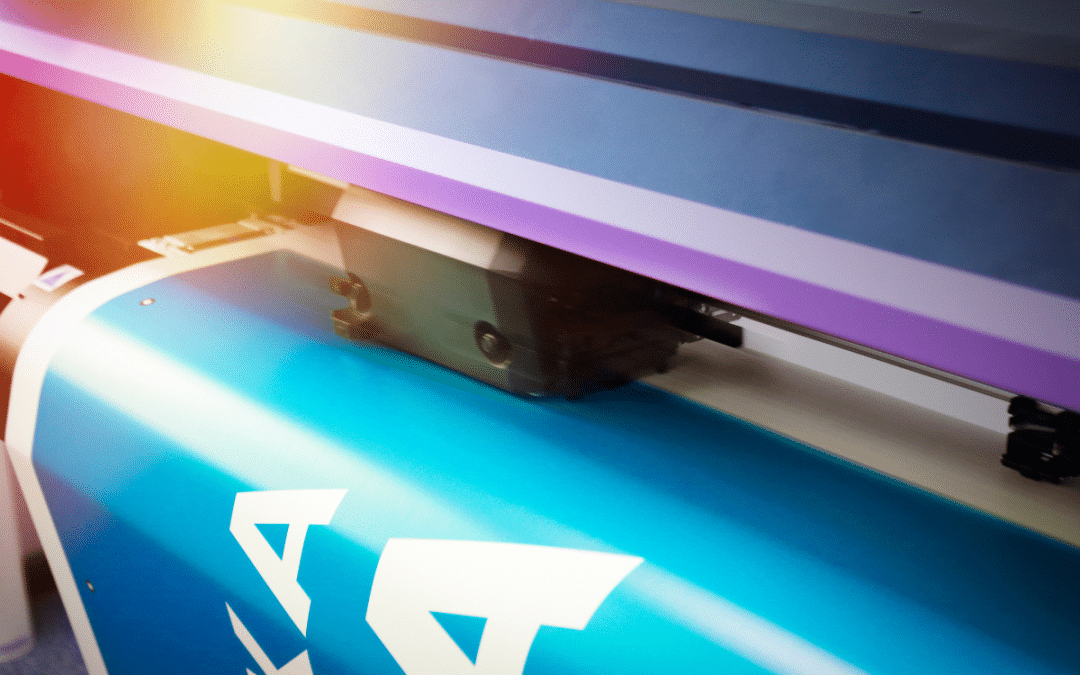

UV printing, short for ultraviolet printing, is a cutting-edge digital printing technology that uses ultraviolet light to cure ink, adhesives, or coatings as they are printed onto a surface. The process ensures immediate drying, resulting in sharp, vibrant colors and durable prints on virtually any material.

Historically, printing relied on ink soaking into paper or other porous surfaces, requiring time to dry. However, as industries began needing faster and more versatile solutions, UV printing emerged as a game-changer. It eliminates drying time, reduces smudging, and opens up possibilities to print on non-traditional materials like wood, metal, glass, and acrylic.

Unlike traditional printing methods, which may involve heat or lengthy drying processes, UV printing provides unrivaled precision and efficiency. Its ability to instantly cure ink ensures every print’s quality is impeccable, carrying a professional-grade finish while being eco-friendly due to its lower emissions and waste.

Why Is UV Printing a Game Changer?

For businesses, the ability to offer faster turnaround times and flawless prints is a significant competitive advantage. UV printing makes both possible. Additionally, its capacity to print on diverse materials allows companies to expand their product offerings, from custom signage to unique promotional products.

Compared to traditional printing techniques, which often have limitations when it comes to material compatibility or color vibrancy, UV printing stands out as highly versatile and high performing. Whether you’re producing eye-catching banners or small personalized items, UV printing delivers excellent results consistently.

Take, for example, a business offering custom promotional items. Imagine being able to print bright, detailed logos onto keychains, phone cases, or even water bottles, all without worrying about smudges or fading. That’s the level of quality and reliability UV printing brings to the table.

5 Reasons UV Printing Is the Future of High-Quality Prints

1. It Delivers Fast, Measurable Results

One of the biggest advantages of UV printing is speed. Because the ink cures instantly under ultraviolet light, prints are immediately ready for use. There’s no need to wait for ink to dry, which significantly reduces production time.

For businesses that rely on quick turnaround times, such as event planners or marketing agencies, this rapid production capability is invaluable. You can go from design to final product in a fraction of the time traditional methods would take.

Not only is UV printing fast, but its measurable results also ensure you can see a clear ROI. Since this method prevents errors like smudging or uneven ink distribution, there’s less wasted material and rework. This efficiency translates directly into cost savings.

2. It Improves Customer Engagement and Personalization

The versatility of UV printing enables businesses to provide highly personalized products. Whether it’s custom signage, unique promotional products, or bespoke packaging, UV printing lets you cater to individual customer needs with incredible attention to detail.

Customers appreciate personalization, and UV printing makes it easy to deliver. For instance, an e-commerce brand can use UV printing to customize packaging with unique customer names or messages, creating a memorable unboxing experience that fosters loyalty.

Additionally, UV printing enhances engagement through its ability to deliver vibrant, high-resolution images. Crisp, visually appealing designs are more likely to capture and hold a customer’s attention, leading to higher engagement rates.

3. It Maximizes ROI with Laser-Focused Targeting

UV printing’s precision helps minimize waste and increase efficiency, which ultimately maximizes profits. Unlike older methods that might struggle with certain materials or intricate designs, UV printing’s versatility ensures every job is done right the first time.

For small businesses, this is a huge advantage. With UV printing, you can confidently take on complex jobs knowing that the technology will consistently deliver top-notch results, all while keeping material costs down.

This method also allows businesses to use smaller print runs while still maintaining cost-efficiency. This is ideal for targeting niche markets or running test campaigns without committing to large, expensive print projects upfront.

4. It Streamlines Your Production and Converts Faster

Time is money, especially for businesses. UV printing streamlines operations by combining high speed with impeccable quality, making it easier to produce larger quantities without sacrificing precision. This efficiency is vital for companies managing tight deadlines or high-demand periods.

Consider a boutique print shop offering custom wedding invitations. With UV printing, they can handle intricate designs, gold foiling, and special finishes quickly, ensuring orders are completed in time for the big day while maintaining stunning results.

Faster production also improves conversion rates. Clients are more likely to return or recommend your services when you consistently meet tight deadlines without compromising quality.

5. It Works Across Various Materials and Budgets

One of the most exciting aspects of UV printing is its ability to print on non-traditional materials, opening up endless possibilities for businesses. From glass and ceramics to textiles and metals, UV printing allows you to create unique, high-quality products that stand out in any market.

For example, a small artisan business could use UV printing to brand wooden home décor items, while a marketing firm might employ it for sleek, modern acrylic signage. With such flexibility, the potential applications are virtually limitless.

Despite its high-tech capabilities, UV printing isn’t limited to big-budget projects. Its efficiency makes it accessible for businesses of all sizes. Low waste, faster turnaround, and consistent quality help keep costs manageable, even for small-scale entrepreneurs.

How to Get Started With UV Printing

If you’re convinced UV printing is the right step for your business, here’s how to begin. Start by identifying your goals. Are you looking to improve your product offerings, attract new clients, or streamline production?

Next, research different UV printers to find one that fits your needs. From smaller models perfect for custom product printing to industrial-scale machines for large volumes, there’s a UV printer for every business.

Additionally, invest in skilled design professionals who can help you create high-quality templates and customize products effectively. UV printing works best when the designs are tailored to both the material and desired outcome.

Common Pitfalls to Avoid

To make the most of UV printing, be aware of potential pitfalls:

- Over-promising capabilities – While UV printing is versatile, it’s important to set realistic expectations based on the printer and materials you’re using.

- Ignoring material compatibility – Not all materials are suitable for UV printing. Ensure you test thoroughly before committing to a project.

- Misunderstanding your audience’s needs – Tailor your products and services to your target market to ensure they resonate with your audience.

FAQs About UV Printing

What’s the difference between UV printing and traditional printing?

UV printing uses ultraviolet light to instantly cure ink, providing sharper, more durable results. Traditional methods often rely on heat or air drying, which can limit material compatibility and increase production time.

How do I know if my UV printing project is successful?

Success is typically measured by the quality of the print, customer satisfaction, and your ROI. Metrics like turnaround time and efficiency also indicate successful implementation.

Can small businesses benefit from UV printing?

Absolutely. UV printing’s versatility allows small businesses to offer unique, high-quality products that attract customers and stand out in competitive markets.

What kind of budget do I need to start?

Costs depend on the type of printer and materials you choose. Entry-level printers are available for small businesses, while industrial options cater to larger operations.

Conclusion

UV printing is transforming the printing landscape with its speed, quality, and versatility. Whether you’re a small business looking to expand your offerings or an established company seeking innovative solutions, now’s the time to explore what UV printing can do for you.

Take a step into the future of high-quality printing today and see the difference this technology can make for your business.

Recent Comments